Structural Film. Light. Transparent and Freedom of Form.

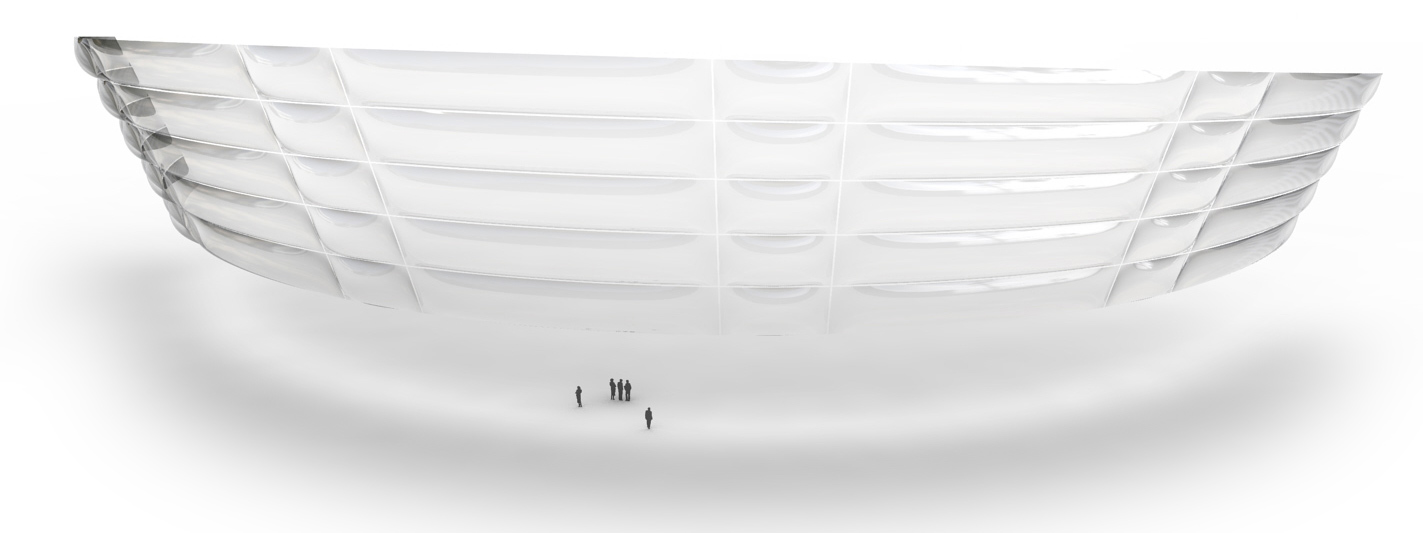

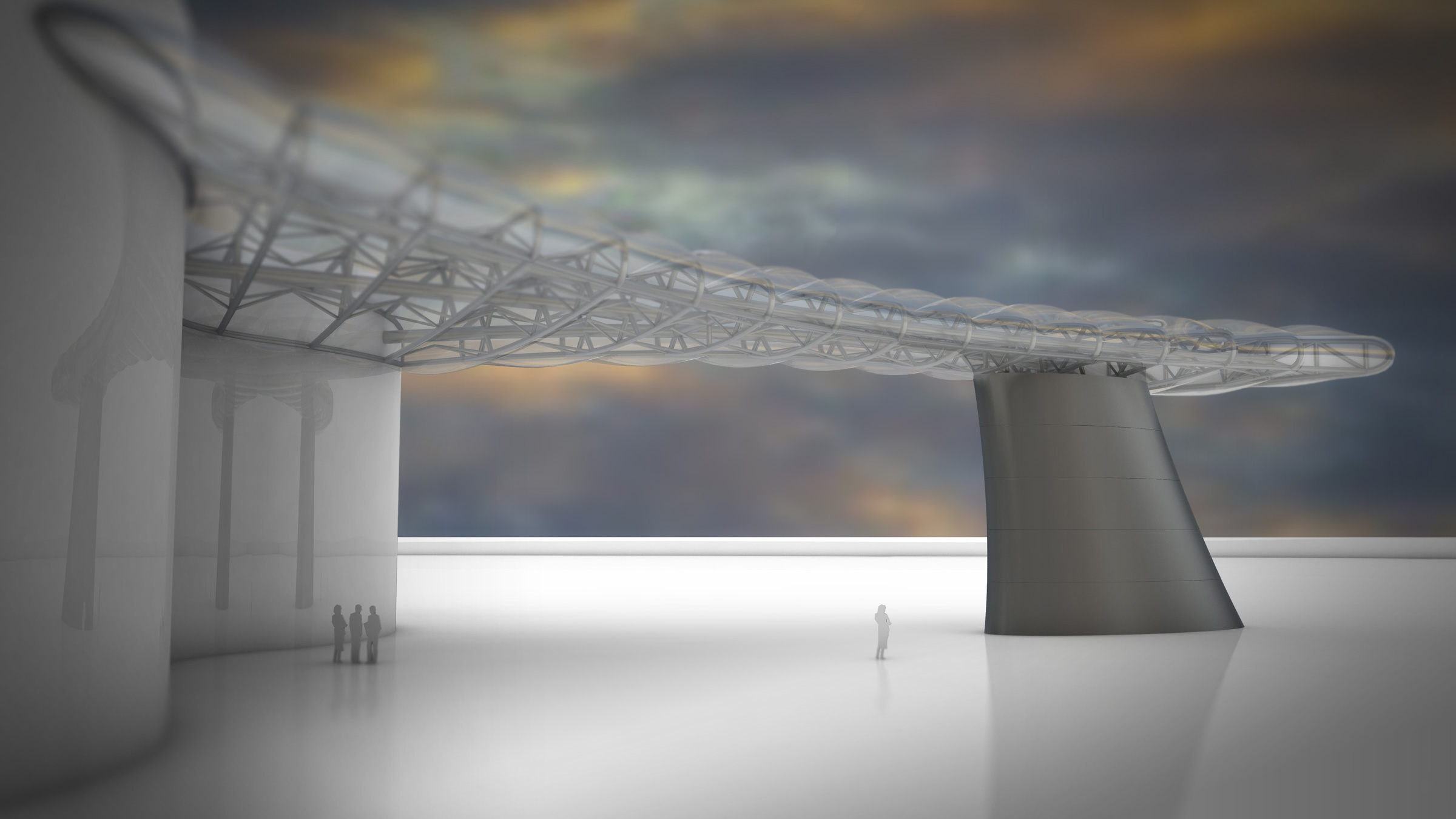

Marina Bay Station, Singapore

Steel Structure and ETFE cushion Canopy

with Novum Structures, 2010

As part of the construction of the metro station "Marina Bay" an open roof in Singapore has been realized, composed of a complex steel frame and covered by two different ETFE film systems: air filled cushions and cable reinforced single layer. The 42 inflated cushions are made of 2 layers each, accumulating to almost 2000sqm of film, 84 layers for a total of approx. 624 cutting panels. The 9 single layer sails, made of 250micron film and reinforced by cables are installed at the peripheral of the steel frame. The projected covering area is approx. 1110sqm

Architecture: Aedas.

Engineering And Execution: Novum Structure

Samuel Fournier Designer:

- Involvement in the structural detailing design

- Complete Formfinding of the ETFE systems (Pillows and Single Layer Sails).

- Cutting pattern generation of the ETFE systems.

Winifred Holtby and Tweensykes Highschool

Atrium ETFE cushion Canopy

with Novum Structures, 2010

http://www.winifredholtbyacademy.co.uk/

Samuel Fournier Designer:

- Formfinding of the ETFE Cushions.

- Cutting pattern generation of the multilayer ETFE pillows.

Petersborough Hospital

Petersborough Hospital Main Atrium, Petersborough, UK

Atrium Enclosing Roof - ETFE Cushion Roof on Steel Arches

with Novum Structures, 2009

A good example of simplicity where ETFE foil can offer also great possibilities. The Atrium of this hospital in the UK was enclosed and covered by a light transparent roof composed of a total of 38 cushions, 10 roof cushions of 8.4 x 3.5m and 28 small side vertical cushions. They are made of 3 layers each, to offer better thermal insulation performance. The light weight of the foil construction allows the use of a minimal supportive structure. The projected covered area is approx. 315 sqm, and the total area of foil used is up to 1255 sqm.

Engineering And Execution: Novum Structures

Samuel Fournier Designer:

- Involvement in the structural detailing design

- Complete Formfinding of the ETFE systems (Pillows and Single Layer Sails).

- Cutting pattern generation of the ETFE systems.

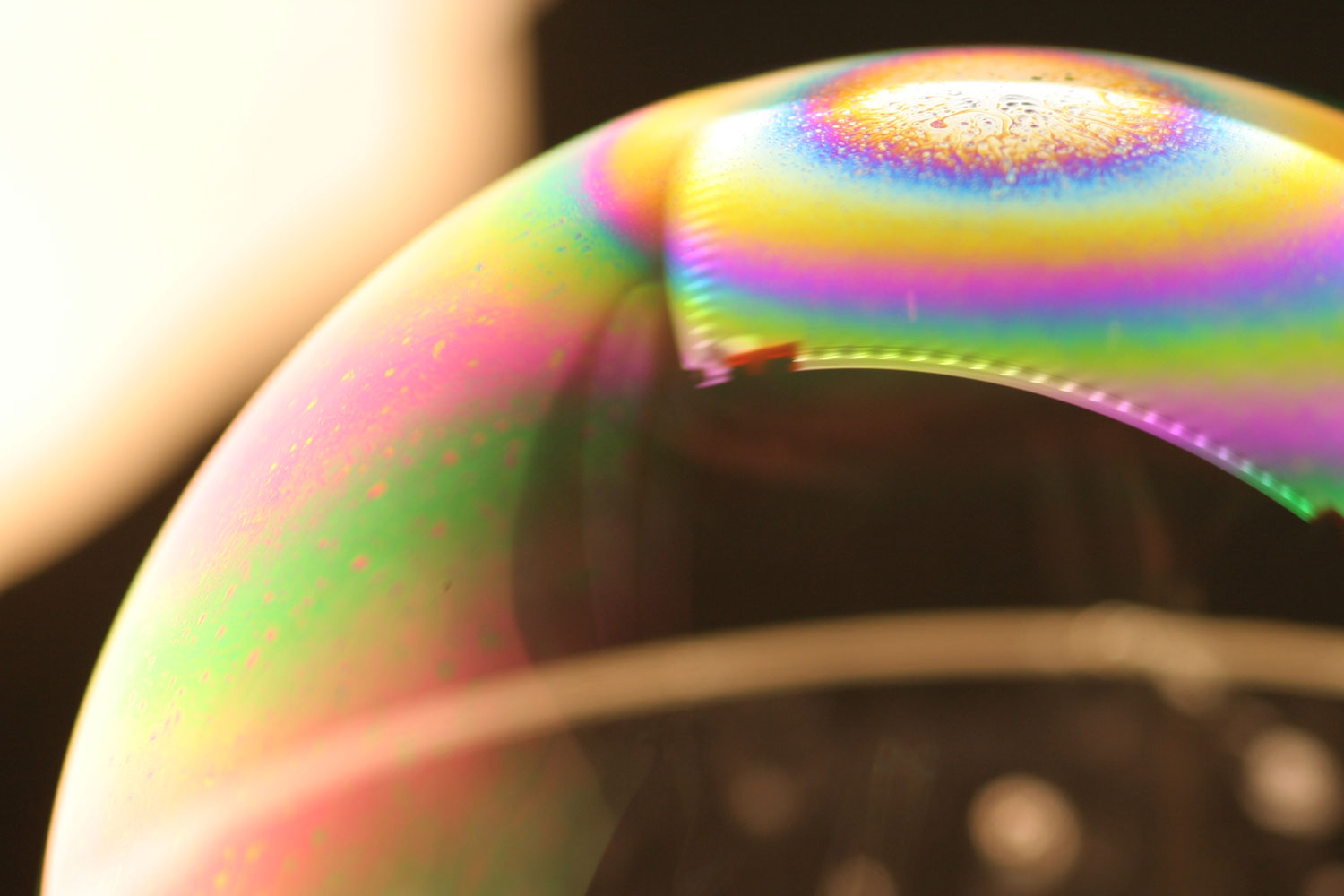

Soap bubbles are a fascination for kids, and also for lightweight structure designers. Bubbles are used as a physical modelling tool to define the form of pneumatic structures, inflated buildings and structural film cushions.

STRUCTURAL FILM refers to Ethylene-Tetra-Fluorine-Ethylene (ETFE) foil structures: architectural elements made of a transparent fluorine-polymer film material. This high performance polymer foil has been used in architecture for more than two decades. Due to its transparency and properties, ETFE has been replacing glass and other transparent/translucent material, offering decisive advantages in building physics, and chosen for its light weight plus the freedom of form it provides. It can be applied as roofs and facades in the construction of public buildings, sport facilities, zoos, greenhouses, swimming pool, etc. Iconic projects such as the Allianz Area in Munich (2005) and the Beijing Olympics (National Swimming Hall and the BirdNest Stadium, 2008) has brought architectural public interest for the material.

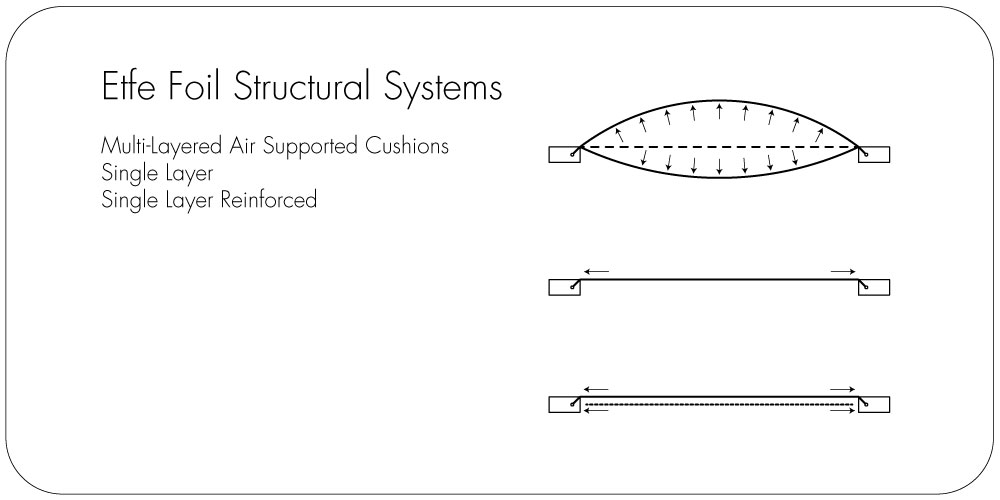

The flexible foil can be stabilized and used structurally in two main configurations: as a single layer under tension, and as multi-layered air supported cushions, where inner pressure is used to prestress the membrane. The film can also be reinforced by linear elements, such as rope, belts or cables, permitting larger span and higher load carrying capacity. Commonly, the membrane panels, or the cushions, are connected to a standard peripheral profile detail, mounted on the main supportive structure. Some special projects may require a particular custom detailing, permitted with this flexible and versatile system. The Air Supported Cushions require an air machine and air supply network, guarantying a given pressure (0.3-0.8kPa) under certain conditions. The air is filtered, dried and tempered air; and the air machine has the necessary backups for security in case of electrical shut down.

The ETFE systems will be calculated and dimensioned based on the different local wind and snow loads, and it case of deflation, the cushions will calculated and designed to resist water pounding (local accumulation of rain water).

Diverse Studies

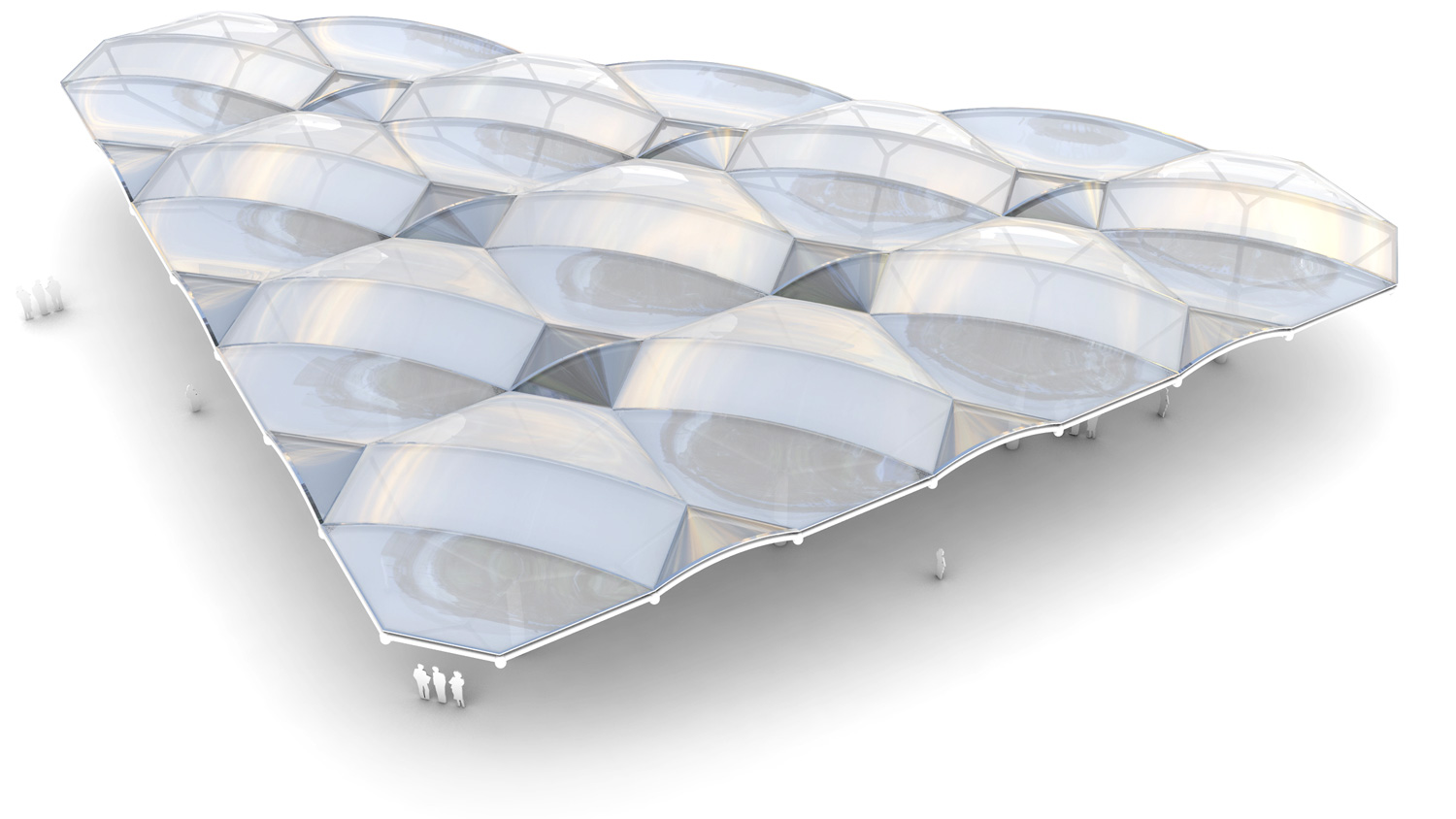

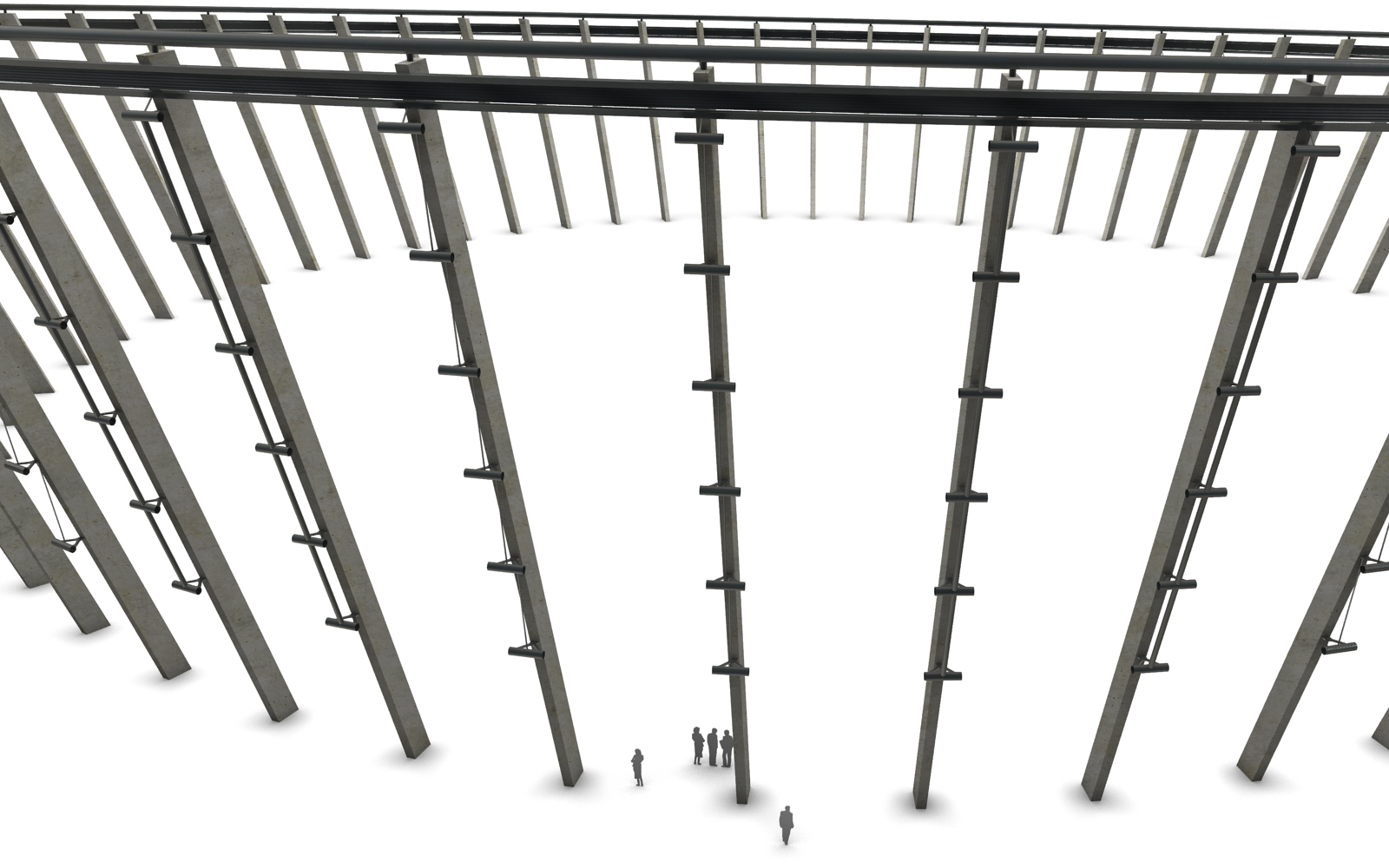

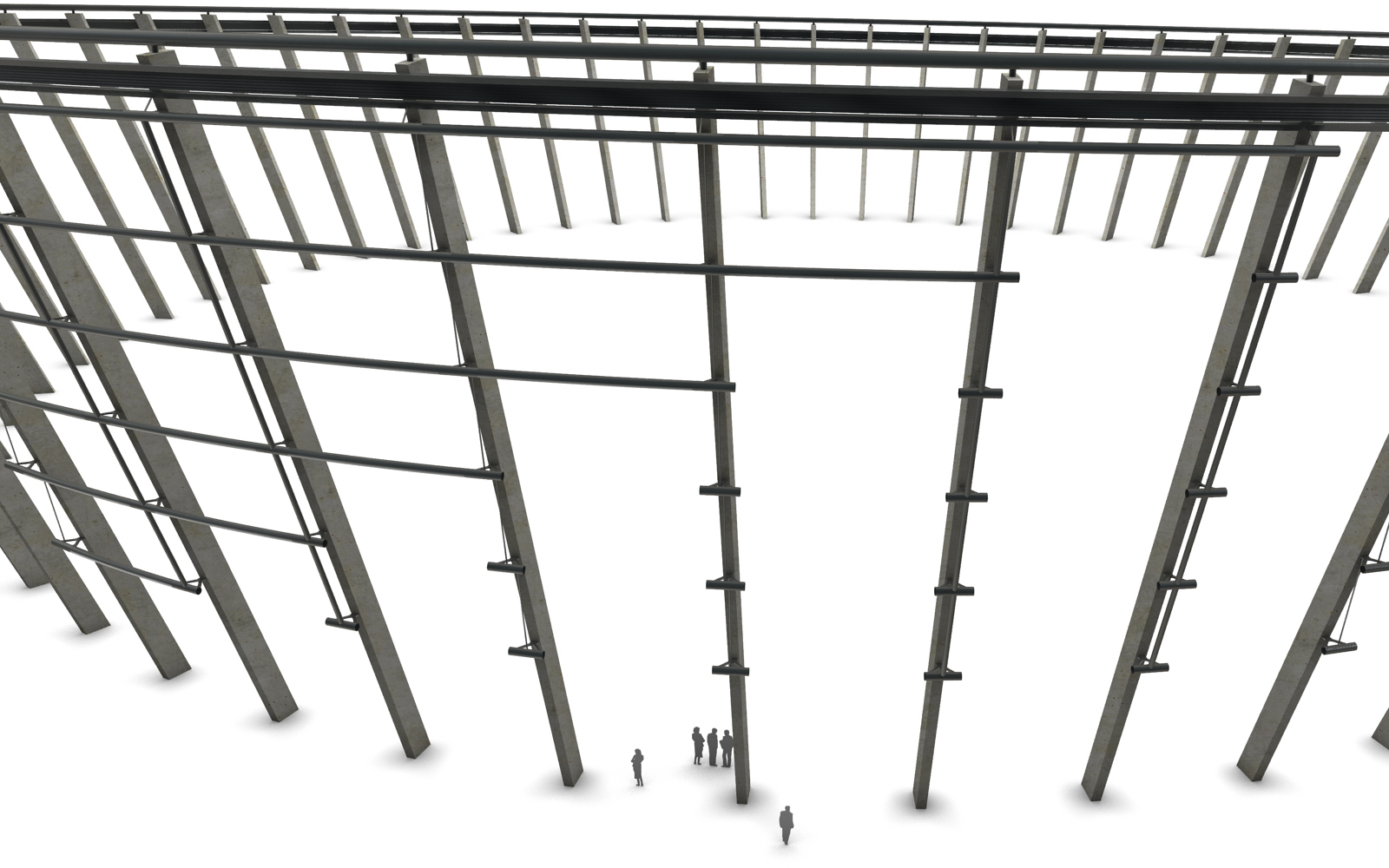

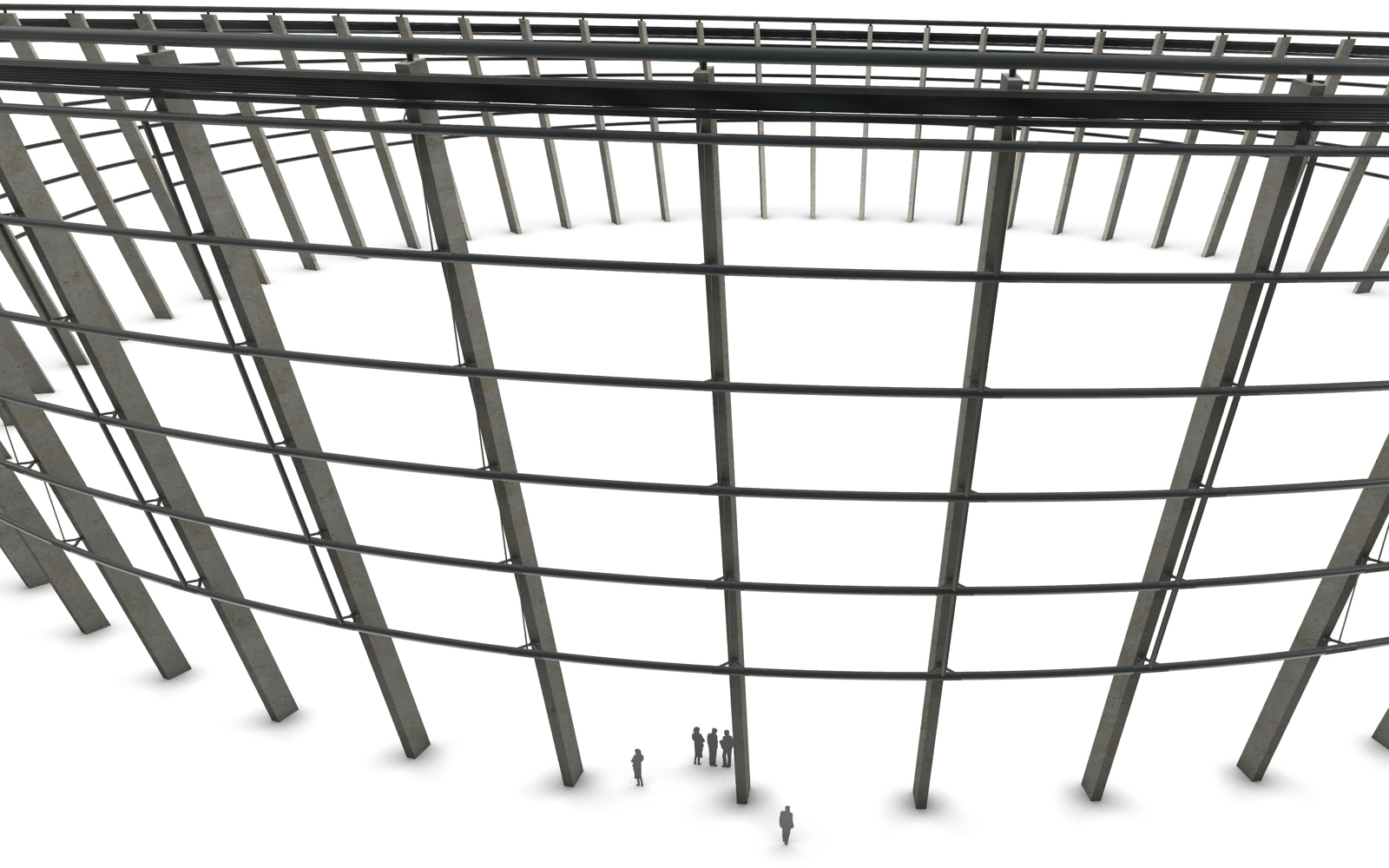

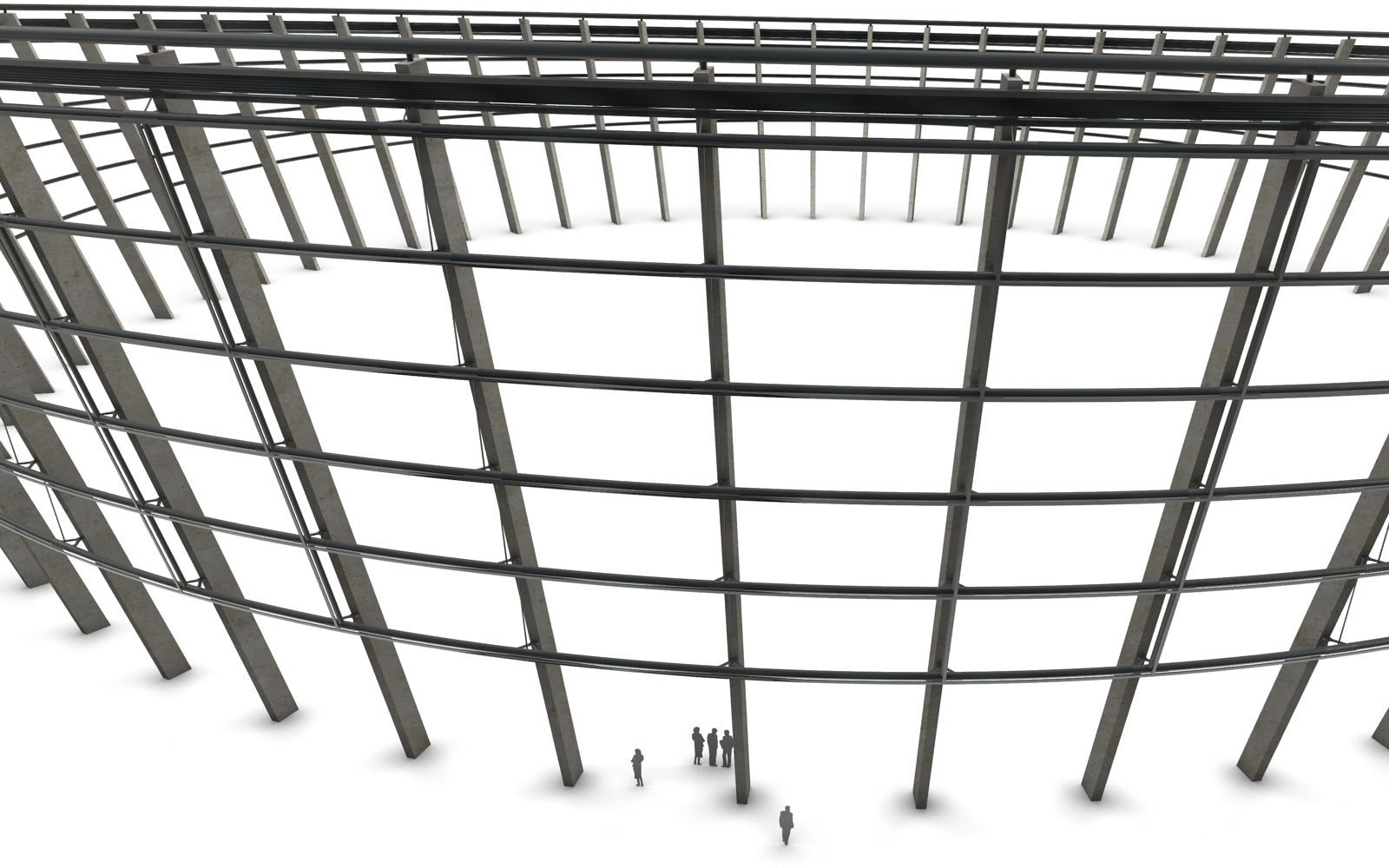

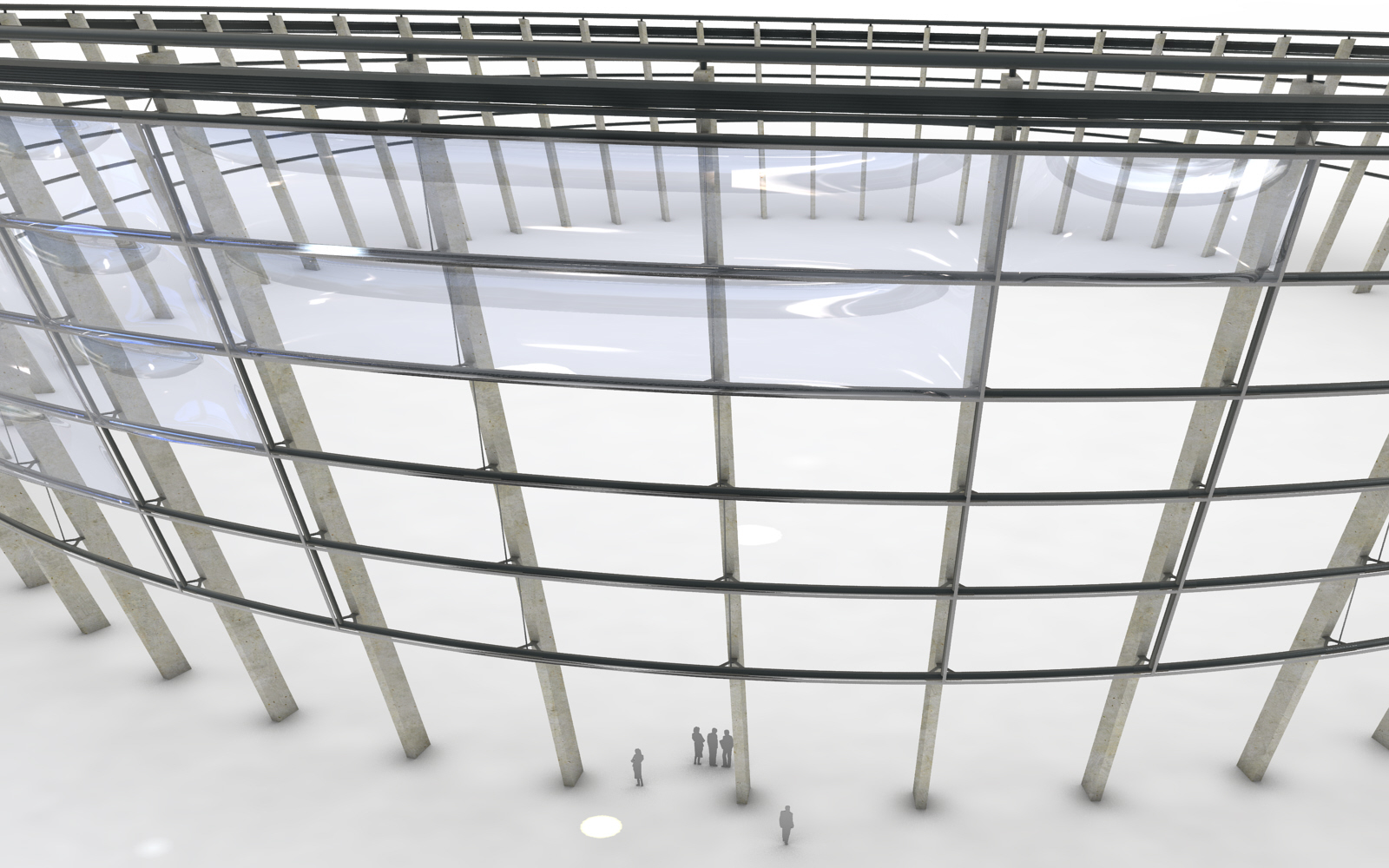

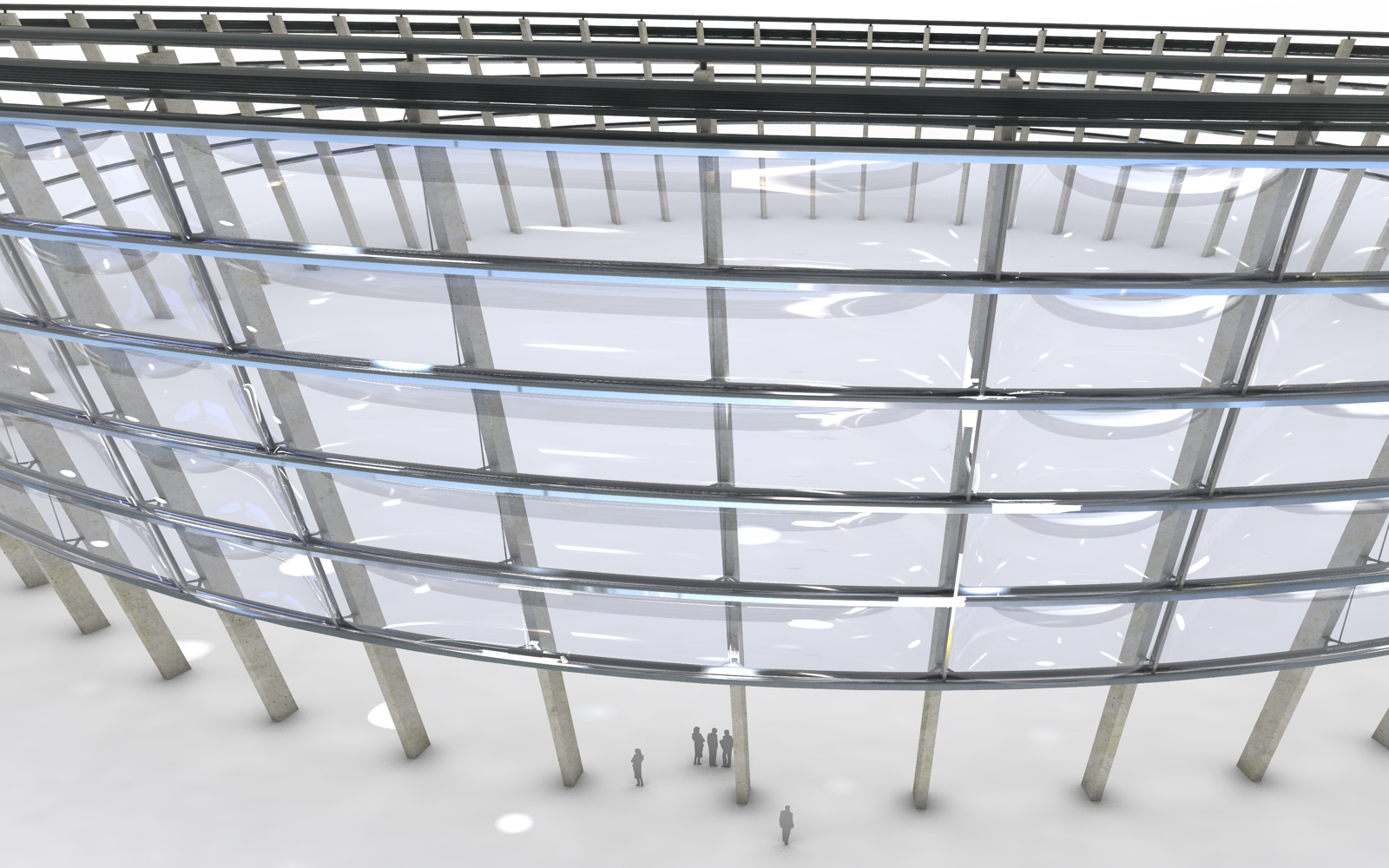

Glasgow Stadium Facade Study

This stadium project demonstrates the use of ETFE cushions as a Facade. The study proposed a constructive system and its method statement, composed of a sub-structure, the profiles and the cushions. In their design, Foster proposed long and short linear cushions, with a width of approximatively 4m. The length of such linear cushions has no real limitation ,as long as production and the installation are capable of handling them.

From simple to complex geometry

Each architect and designer has their own taste and style and some will express fantasy trough geometrical complexity, while others, would rather go for purity and simplicity. ETFE foil and systems offer this great freedom, limited by what is physically and statically feasible! Usually, Lightweight Structures Designers love challenges and it is always exciting to inspire and be inspired by architects daring to take design one step further.

Each projects are unique, for its form, specifications and complexity. The structural film structural system is adapted and tailored to the architect and client requests.

Single Layer Systems . Foil and Cables

A single layer of a clear foil, spanning large surfaces and creating transparent roofs or facades, at the fraction of the weight of glass. This design method is very similar to planning tensile membranes made of composite material, although the material behaviour is different. The big difference is: it's transparent!

Contrary to textile, foil is an amorphous material and it has no fibre reinforcement giving the possibility of achieving larger spans and higher load carrying capacities, plus those transparent sails will be reinforced by a cable network. This system doesn't require any air supply, it only uses tension. To improve building physics performance, multiple tensile layers of foil can be applied, to reach similar thermal insulation values as inflated cushions. Support free and large span roofs and facades can be made of structural film at a fraction of the weight of a steel-glass roof. The flexible foil will permit topologies almost impossible to be realized with brittle material.

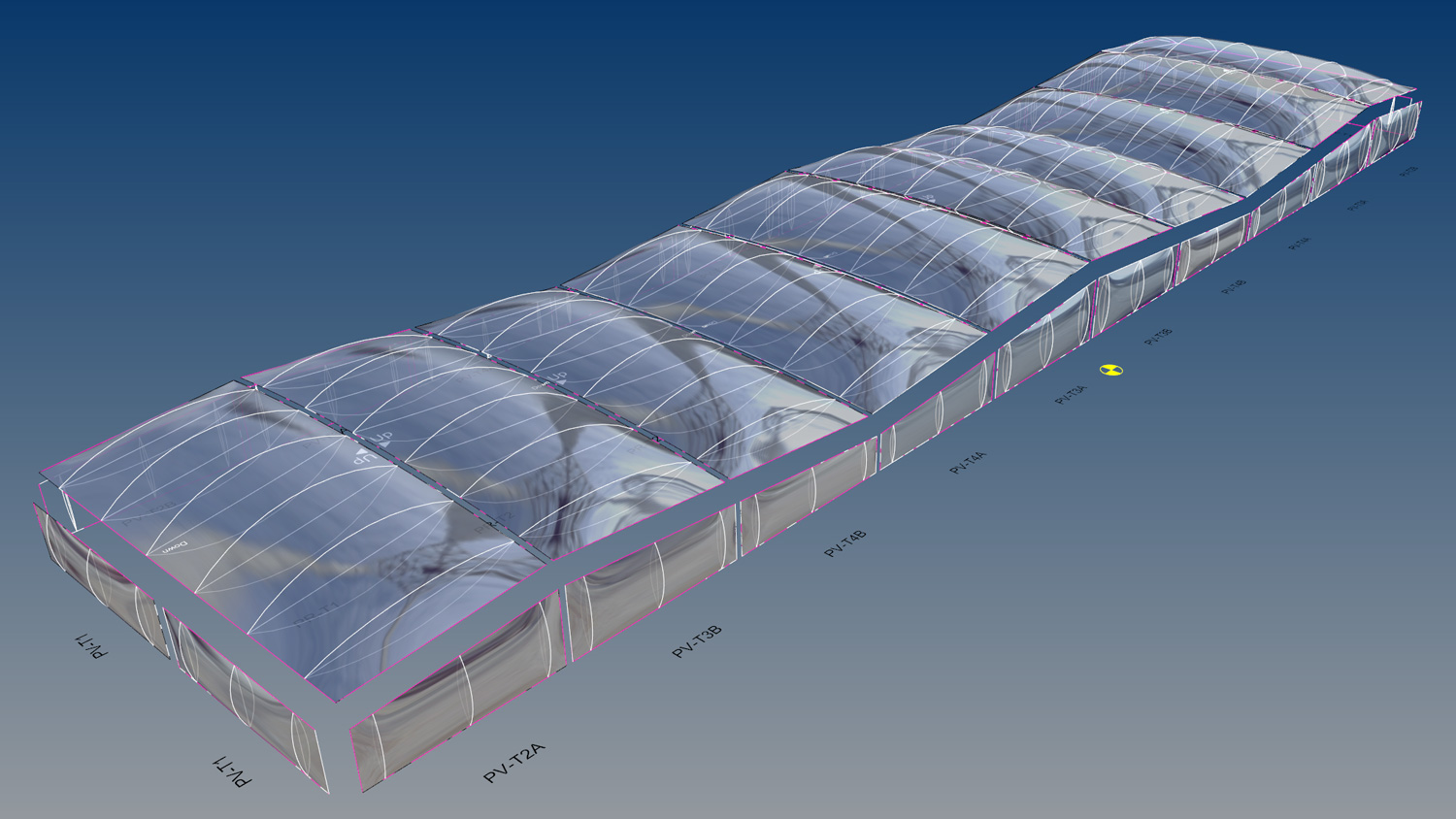

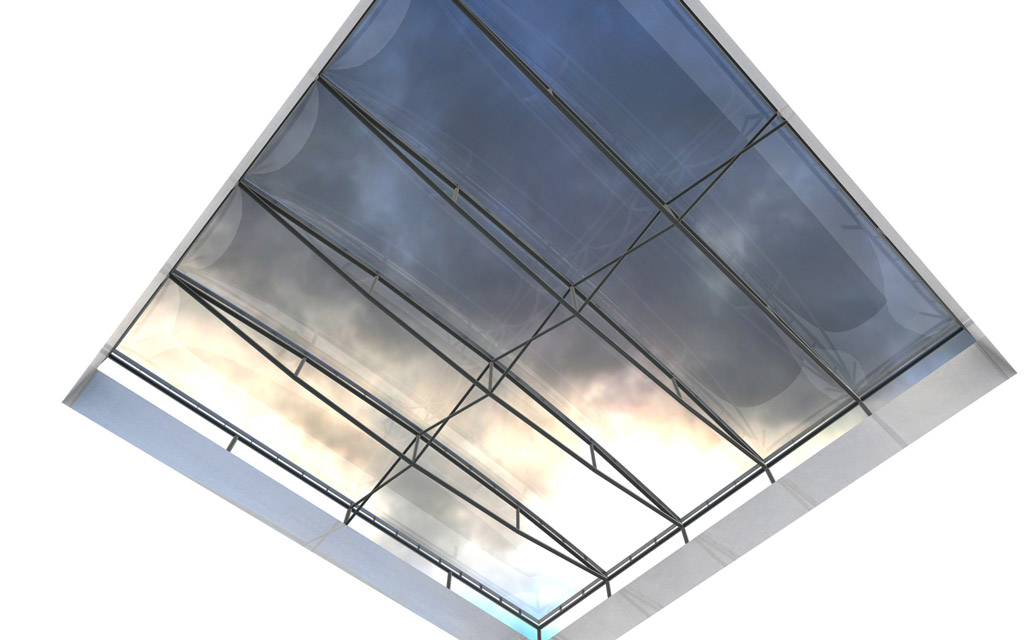

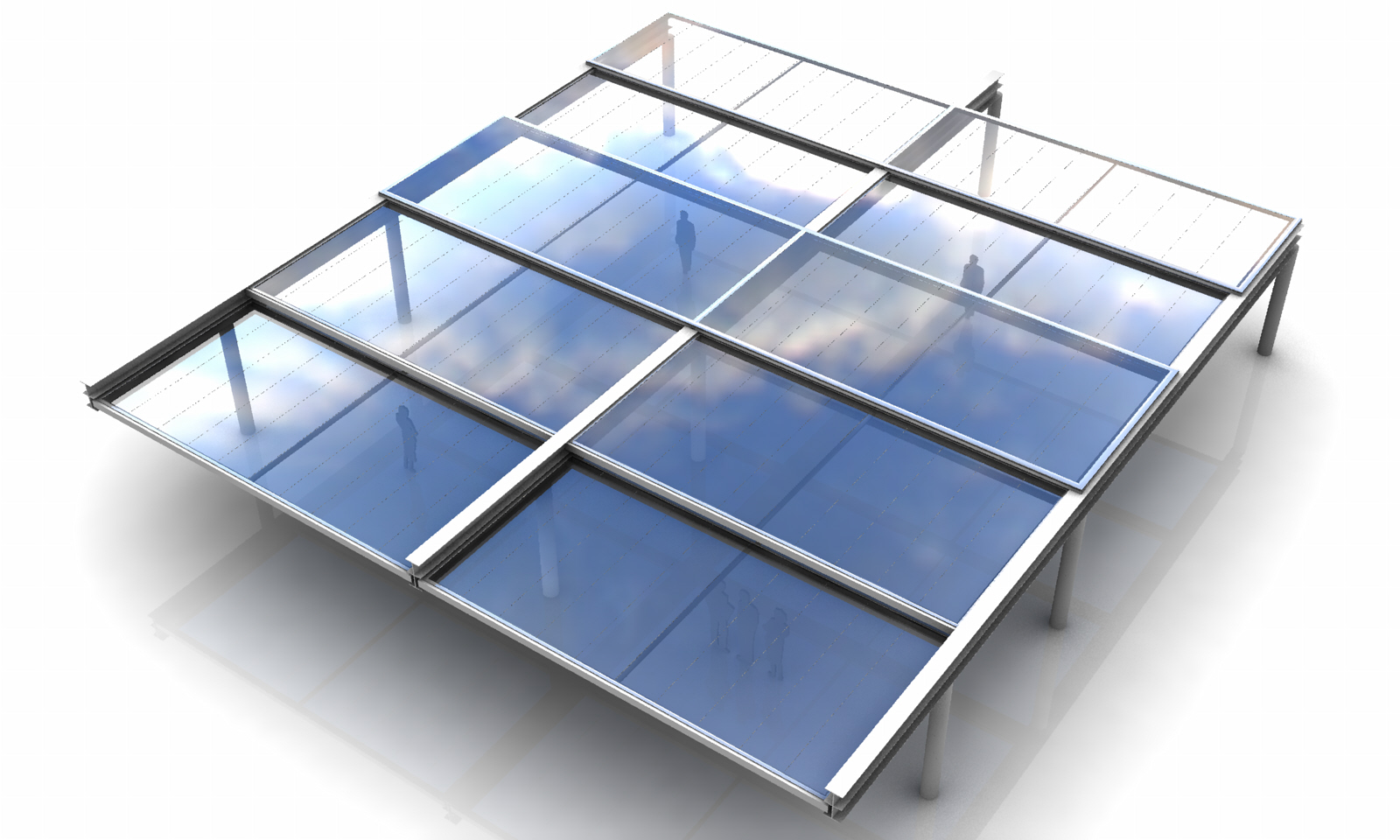

Talima Project Study - Retractable Single Layer ETFE roof.

with Novum Structures, 2009

A retractable roof was proposed for the " Talima" project in Greece. The construction code in that country pushes architects to propose retractable roof systems.

Transparent ETFE panels, reinforced of cables,and mounted on a retractable steel frame system were proposed. The light weight film allows large fields to be covered, while the supportive frame required is definitely lighter than that needed if glass were used, and the light weight is surely less demanding on the retractable mechanic system.

A Quick View in the Production

The cutting patterns are generated from the 3D geometry and are provided to production. A CNC machine will cut those patterns with high accuracy. The panels are then preassembled in the right order and welded on welding machines specifically set to process this high performance polymer material.

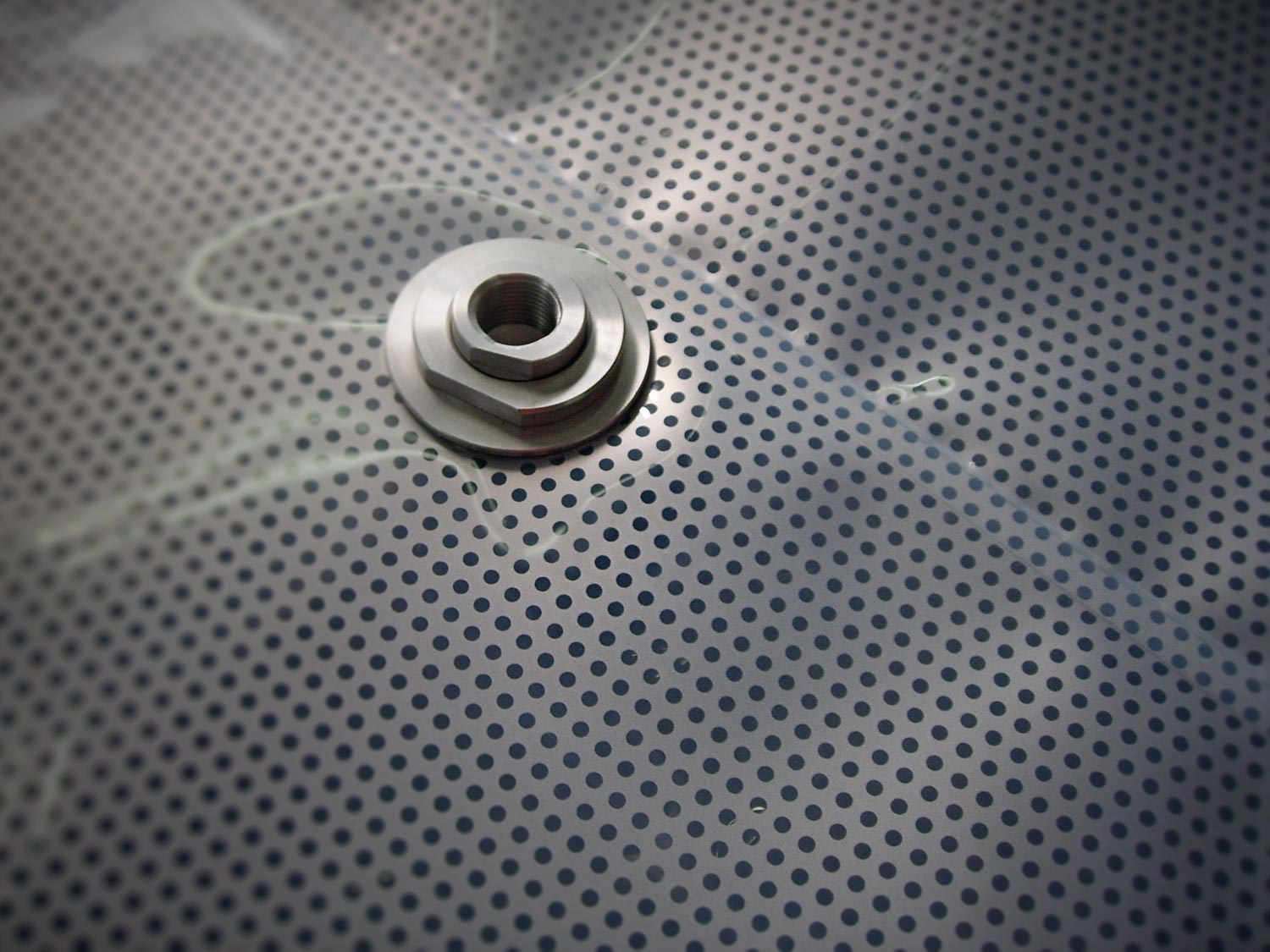

Once the main panels are assembled, all details and boundaries will be added. In the case of cushions, the air supply valve will be fixed and the multi layered panels will be assembled together at the border with a keder detail. This final process will seal the cushion and make it almost completely air tight.

Each of the pieces are handled with care, folded and pack according to the installation sequence.